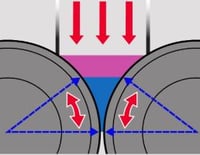

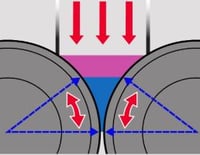

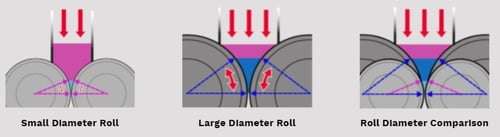

The pre-compression force is supplied by the vertical feed screw. This force is necessary for the rolls to draw the material into the nip region and properly compress the material.

Whether you need to achieve a specific particle size and distribution for tablet compression, or mill heat-sensitive materials, Fitzpatrick can provide the best solution to fulfil your specific processing objectives.

At Fitzpatrick we are committed to improving the performance and profitability of our customer’s powder processing operations by supplying equipment that incorporates performance, reliability, and longevity.

Recognized as the most trusted name in roller compaction technology and dry granulation equipment for more than 70 years, our customers are supported by world-leading applications and development experts, offering budget-friendly, industrial-strength, high-performance roll compactors for dry granulation processing, with each new generation of machinery incorporating seven decades of knowledge.

Fitzpatrick roller compactors offer a truly scalable equipment growth path. As customers progress from research & development all the way through to full production, results obtained on smaller models are fully transferable to larger systems.

With continual investment in customer-driven innovative solutions to address market needs, Fitzpatrick provides long-term global support via their highly technical customer service and spare parts network.

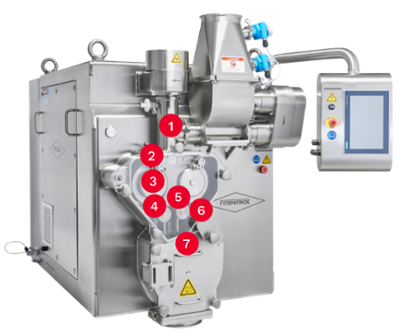

Acknowledging that each individual process requires specific roll compactor operating features, Fitzpatrick offers two distinct model ranges; the IR (Interchangeable Rolls) Series and the CCS (Contained Compaction Systems) Series.

Both the IR and CCS-Series models utilize the world-class FitzMill™ to mill and granulate the ribbon. Process flexibility is maximized by Fitzpatrick’s unique ability to select either a knife or bar rotor, in addition to having access to an extensive range of perforated screens, including round-hole, rasp, and Conidur™ options.

The pre-compression force is supplied by the vertical feed screw. This force is necessary for the rolls to draw the material into the nip region and properly compress the material.

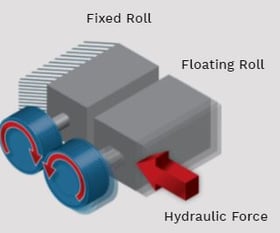

Roll horizontally oriented to assist deaeration and pre-compression.

The vertical feed screw deaerates and compresses powder before compaction by the rolls. Co-ordinated control of these components is critical to optimizing densification.

The floating roll ensures consistent pressure. A dual hydraulic system ensures ‘floating’ rolls precise force for uniform compacts. Precise parallel roll forces are achieved using linear bearings.

Roll gap monitored via a linear variable differential transducer. Automatic gap control is achieved through operator interface. No external adjustments are required.

Roll surface selection is product-dependent. Establishes friction between product and roll surface.

Two milling alternatives:

Instantaneous & continuous compacting of powders

The CCS-Series provides a truly scalable equipment growth path. Offering high containment, progress from R&D to full-scale, high-capacity production-scale models, with fully transferrable results at each stage.

EXPLORE

The IR-Series of roller compactors offers different scales of production capacities from pilot to full-scale production systems, offering the flexibility to increase powder density and enhance flow characteristics.

EXPLORE%20Equipment/PNGS/LCS-roller-compactor.png)

Ideal for R&D or smallest volume production. The Lab Compaction System with a high-precision, twin feed screw system, delivers high-performance dry granulation with production-scale capabilities.

EXPLOREHigh Containment Roller Compactor models, fully contained and scalable from lab to production. Our unique dual-screw feed system design ensures the ideal conditions are created right from the outset at the critical nip area of the rolls.

Ideal for R&D proof of concept research

The CCS220 model is a compact, mobile unit which is easily movable. With consistently sized roll diameter across the CCS-Series of machines, scale-up to production size equipment is easily achieved.

Lab/pilot conversion kits allow for reciprocal conversion between the CCS220 and CCS320 models (pressure/capacity dependent).

Suitable for mounting in-wall, free-standing, portable or in an isolator/flow booth.

Ideal for small volume/pilot-scale production

Designed with three rolls, the CCS320 model is a compact, mobile unit which is easily movable. With consistently sized roll diameter across the CCS-Series of machines, scale-up to production size equipment is easily achieved.

Lab/pilot conversion kits allow for reciprocal conversion between the CCS320 and CCS220 models (pressure/capacity dependent).

Suitable for mounting in-wall, free-standing, portable or in an isolator/flow booth.

Suitable for mid-sized production-scale capacities

The CCS520 model is available as a free-standing or in-wall installation. In-wall installations minimize clean room space requirements and allow for internal maintenance access without the need for PPE.

The optional Product Containment System (PCS) minimizes operator exposure to active ingredients for additional security and prevents product loss or contamination.

Simple straightforward design with clean-in-place (CIP)/wash-in-place (WIP) capability.

Designed for large production-scale capacities

The CCS720 model is available as a free-standing or in-wall installation. In-wall installations minimize clean room space requirements and allow for internal maintenance access without the need for PPE.

The optional Product Containment System (PCS) minimizes operator exposure to active ingredients for additional security and prevents product loss or contamination.

Simple straightforward design with clean-in-place (CIP)/wash-in-place (WIP) capability.

The maximum volume capacity model in the CCS-Series

The CCS1025 model is the largest capacity of the CCS range of roller compactors and comes as a free-standing or in-wall installation. With the in-wall design, the technical area is entered from the back for ease of use and does not require any PPE.

The optional Product Containment System (PCS) minimizes operator exposure to active ingredients for additional security and prevents product loss or contamination.

In addition, a sheet-breaker is also available as an option to increase the efficiency when milling broader ribbons.

For applications requiring a reduced level of containment, our IR-Series affords varying options of production capacities from pilot-scale to full-scale. Recognized worldwide as high-performing technology for Dry Granulation, the IR-Series offers the flexibility to increase powder density and enhance flow characteristics, improving downstream performance results.

Pilot-scale or small volume roller compactor,

ideal for proof-of-concept applications

The IR520 model is the ideal partner in pilot-scale or small volume roller compaction applications.

Results achieved on this machine are fully scalable to larger production volumes.

As a free-standing unit, complete disassembly of the contact parts enables thorough cleaning that is quick and easy to carry out.

Full-scale production roller compactor, where containment is less critical.

Manufactured with the Fitzpatrick high-precision, twin feed screw system, the IR4LX10D roller compactor has a strong and robust design for durability in full-scale production applications.

As a free-standing unit, complete disassembly of the contact parts enables thorough cleaning that is quick and easy to carry out.

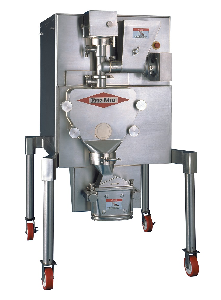

Scalable benchtop, high-performance dry granulation with production-scale capability.

Ideal for proof-of-concept work or trial batch production

The LCS is a low-volume benchtop system that processes powders with the same pressure as larger production-scale roller compactors. With a choice of roll surfaces, this machine is manufactured with a high-precision, twin feed screw system which ensures your development projects can progress from the lab to production with confidence.

Complete disassembly of all contact parts enables thorough cleaning that is quick and easy to carry out.

Optional touchpad control of all independent feed and compaction variables as well as cGMP software.

The Fitzpatrick Company, a division of IDEX MPT, Inc. is committed to improving the performance of our customer’s powder processing operations. Our range of products, quality service provision and expert knowledge help our customers succeed.

© Copyright IDEX 2025

To ensure you make the most of your equipment, we offer a comprehensive range of spares, maintenance and support packages.

If you need a quick answer, fill in your question below and we'll email you right back.